Product Development Timeline

Deep Orange is a part of the automotive engineering program at Clemson University. The 24-month program implements the “engineering studio” approach to teaching by immersing students in the EOM setting. Below is a timeline of what to expect during each phase of the Deep Orange program.

Grand Challenge

Each project addresses a real-world grand challenge related to sustainable mobility. (ex: youth mobility, aging drivers, urbanization). It requires the students to understand societal trends and future legislation.

Market Analyses and Brand Essence

As part of the curriculum, market analyses are conducted to create a better understanding of the psychographics and demographics of the target audience. Each project is sponsored by an OEM and the students must understand the OEM’s brand heritage to align their concepts with the brand essence of the sponsor.

Ideation

During the idea generation phase, the engineering and design students will jointly create a value proposition taking the customer, the brand and the grand challenge into consideration.

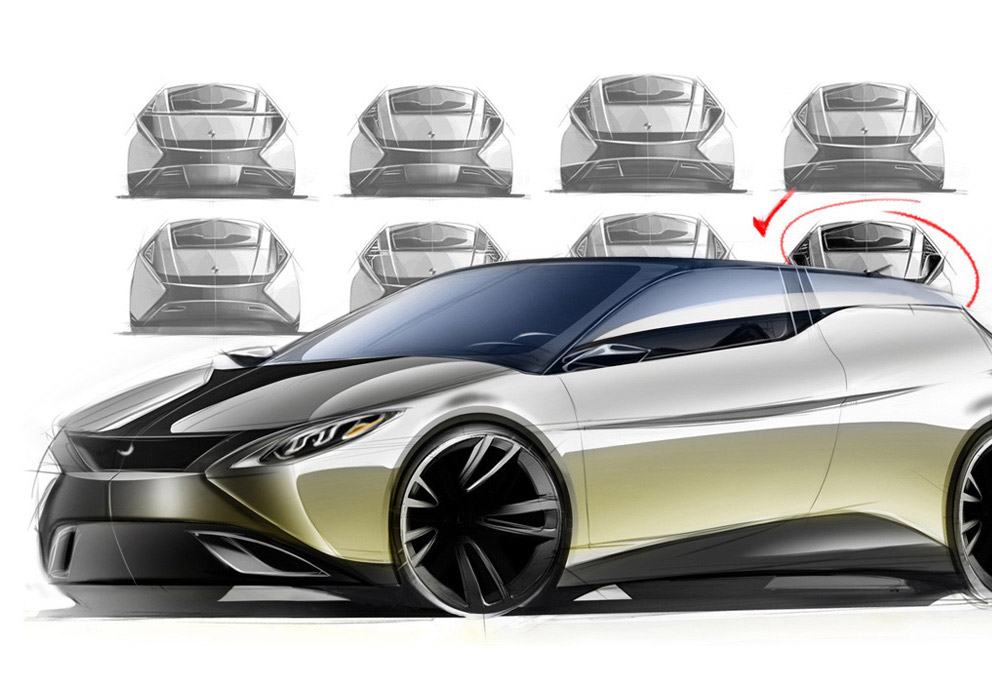

Initial Vehicle Concepts

The final deliverables of the definition phase are 10-15 competing concepts. Design and engineering students take inspiration from fashion and other non-automotive domains to develop their concepts. One concept is selected for further detailing and realization.

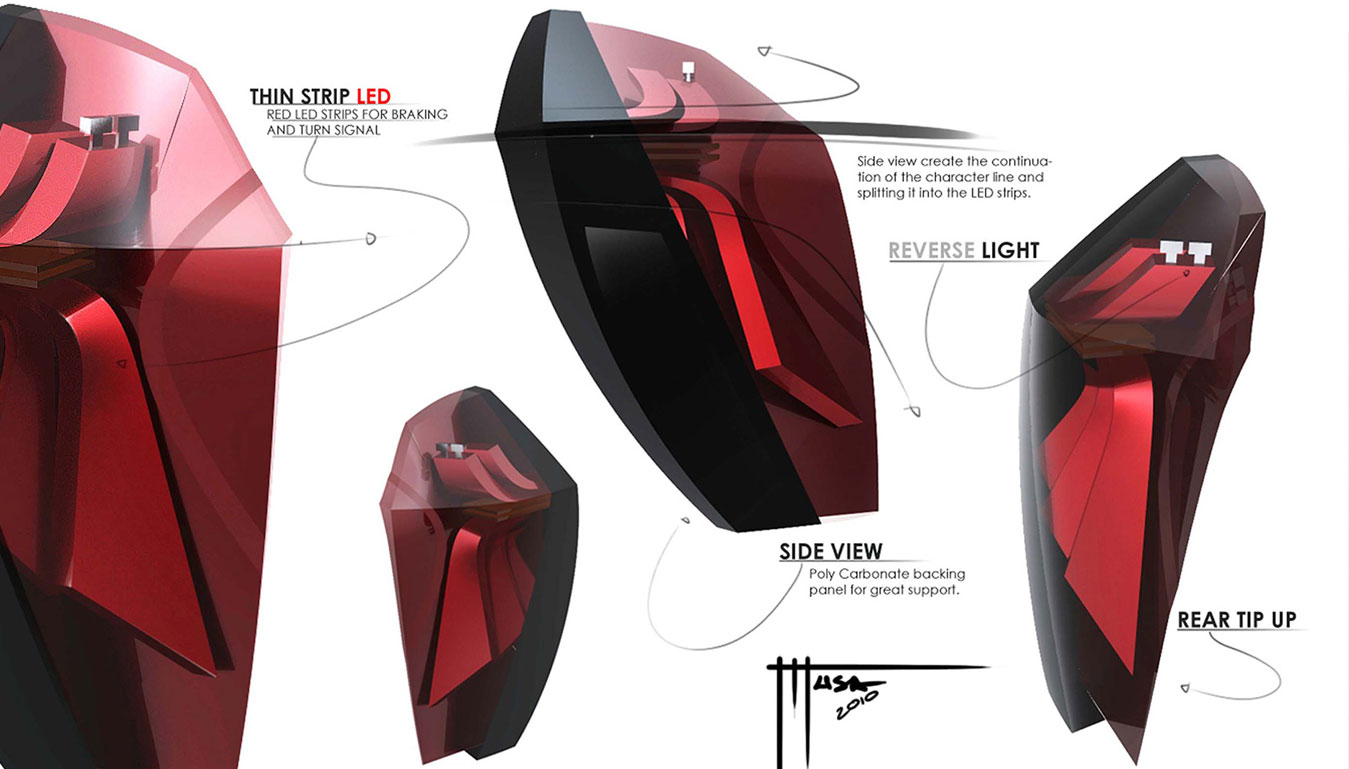

Design Detailing

The exterior/interior design selected will be further detailed by making quarter-sized models in clay supported by digital computer software to render the surfaces. The engineering students provide the packaging details for the occupants, powertrain and chassis.

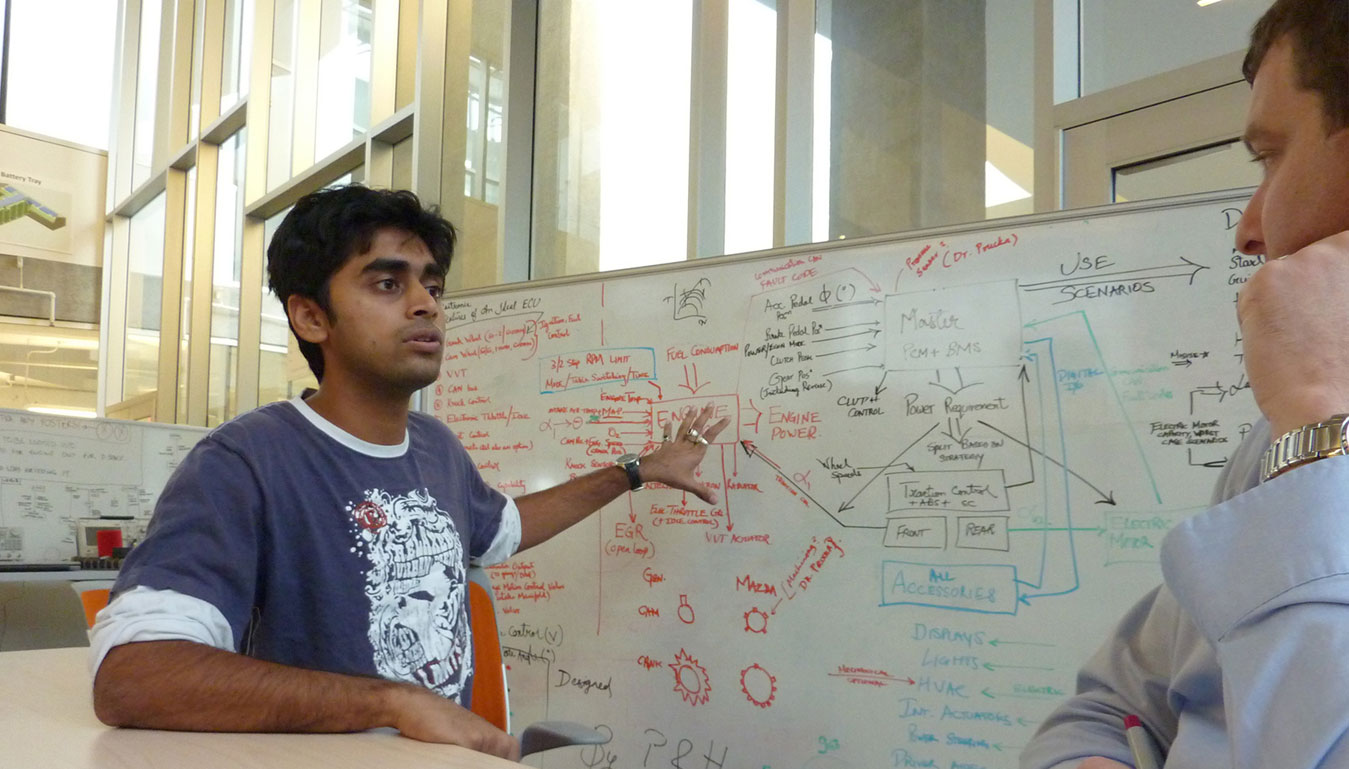

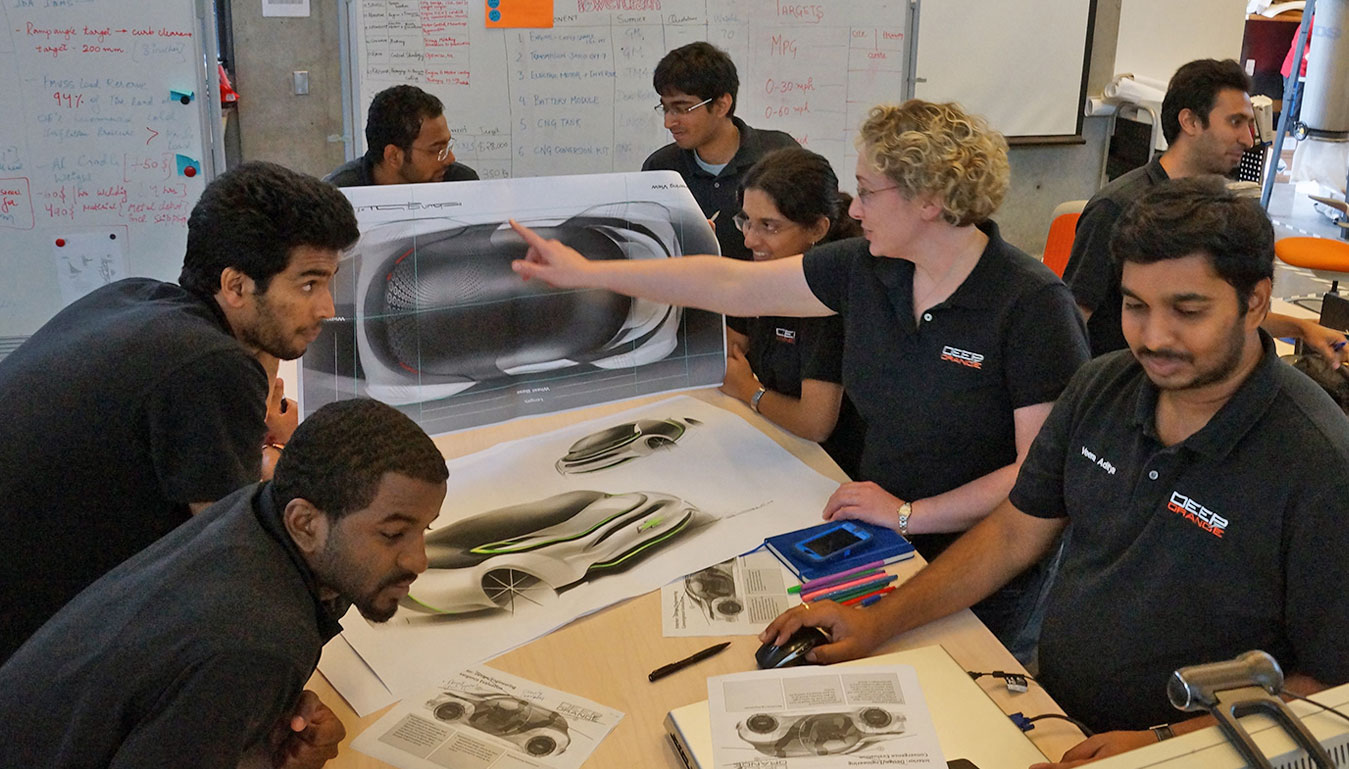

Professional Mentoring

Students are trained to sort through data, identify seminaries and produce a big picture. Students then have the opportunity to interact with industry professionals who train them to sell their ideas clearly and concisely. The interaction allows them to receive detailed feedback and suggestions for improvement.

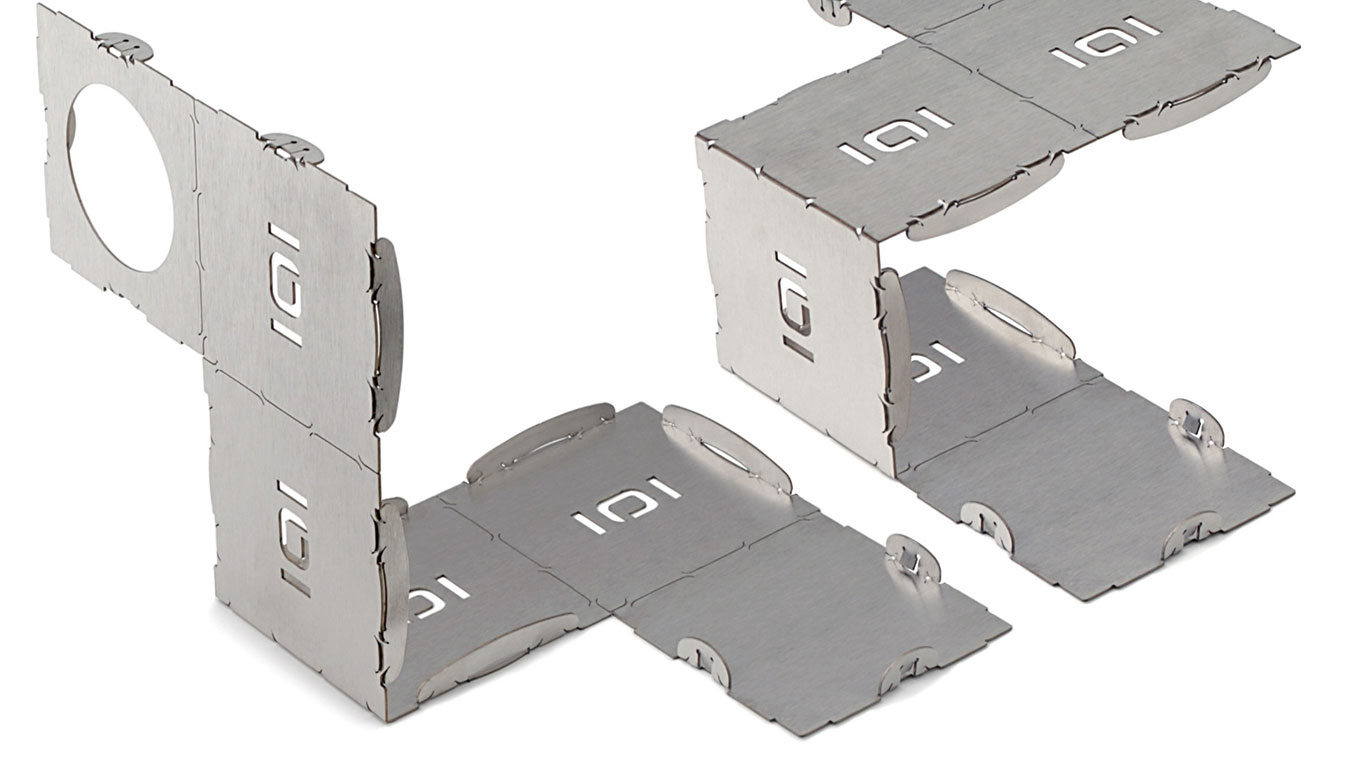

Manufacturing Innovations and Project Status

Students are encouraged to explore and implement disruptive technologies, such as lighter gauge materials folded into innovative, high-load-bearing structures formed with simple, low-cost fixtures. The status and maturity of the project are captured every 4-6 weeks during design reviews.

Design-Engineering Convergence

At major project review milestones, the design and engineering work will be overlaid to identify critical geometric, functional, manufacturing or legislative issues. Both designers and engineers will have to work out a compromise.

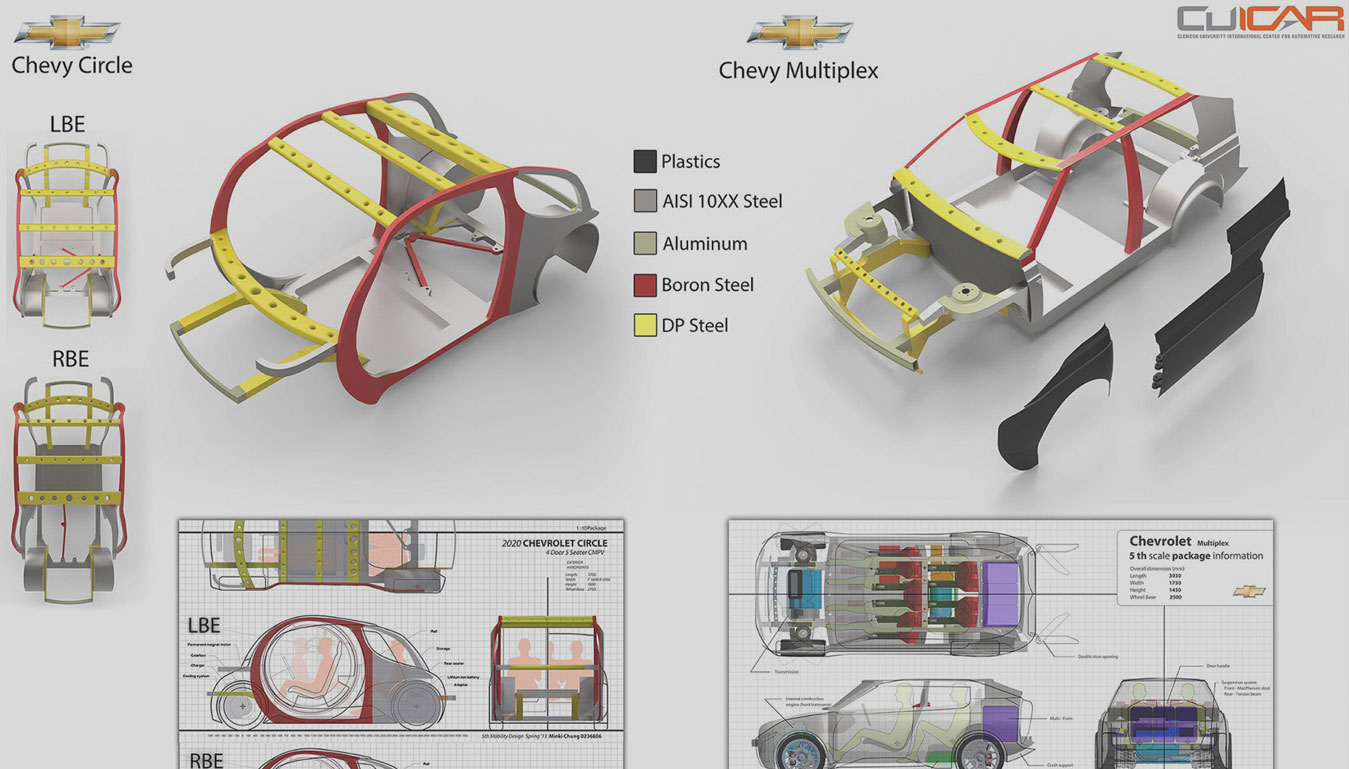

Computer Aided Design

In the first 14 months of the project, computer aided engineering and design tools are used extensively to drive the project maturity supporting design, sizing and validation of component, subsystem and full vehicle level properties.

Digital Mock-ups and Review Meetings

Digital mock-ups are created with 3D software to allow for multiple design iterations in a shorter amount of time. Every 4-6 weeks, the project sponsor will receive a status update on the project. Besides the achievement of vehicle-level properties, the cost, weight, build progress and timing are also reported.

Usability Testing

Paper prototypes are used to obtain feedback from external end-users to identify problems and guide the design. The process is repeated until end-users find the design satisfying and easy to use.

Industry Collaboration

The project is an open-collaboration initiative allowing industry partners to work with students implementing, exploring and showcasing novel ideas.n satisfying and easy to use.

Implementation

The built-phase of the vehicle concept allows the students to implement the skills and knowledge that they have gained throughout their program of study.

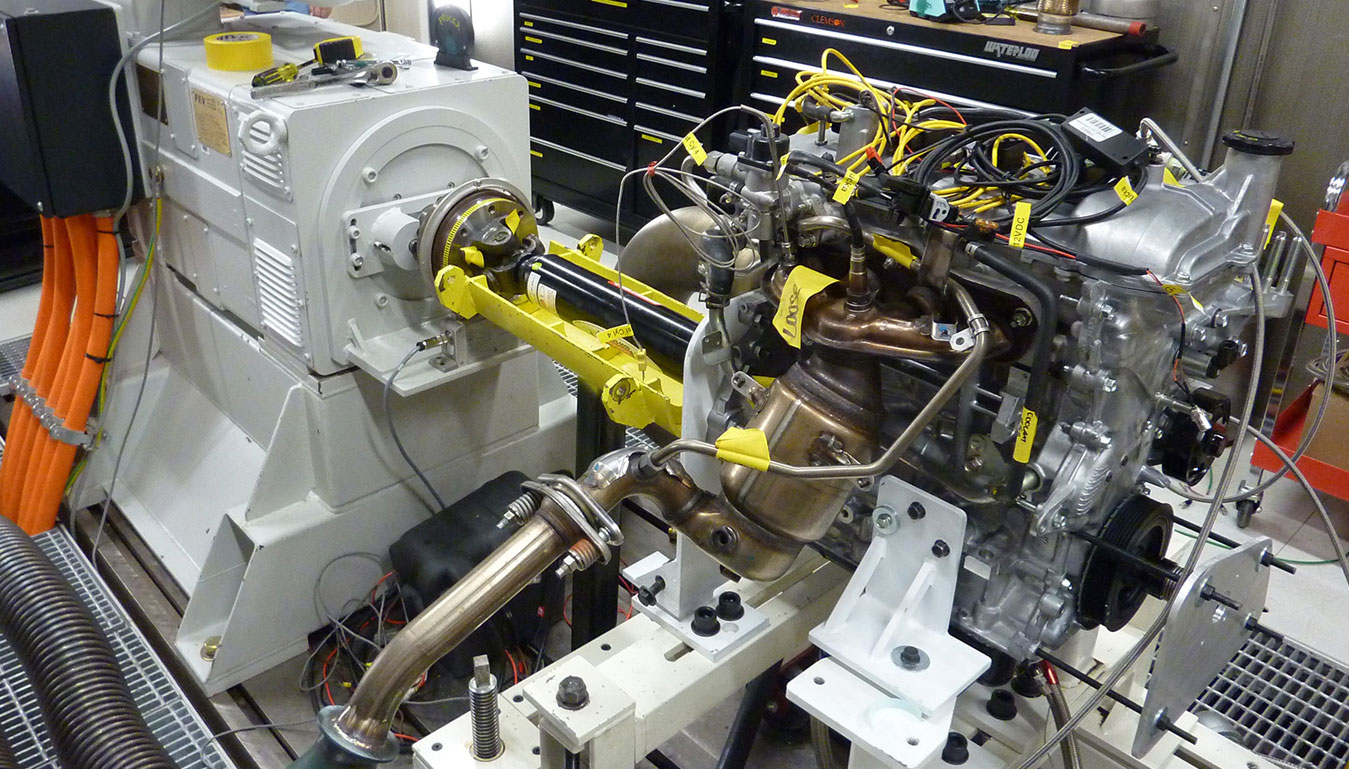

Systems Integration and Component Testing

The design and manufacture of future vehicles require the integrated application of concepts in disciplines ranging from engineering and information technology to business and human factors. Subsystems and components are also tested and calibrated before they are assembled into the vehicle concept.

Full Vehicle Validation, Graduation and Marketing

In the last phase of the project, the functionality of the vehicle prototype is validated against the targets that are defined in the strategic planning phase. After project completion, the graduates are involved in showcasing the project outcomes at major venues such as the SEMA Show and LA Auto Show.