Deep Orange 7

ENGINEERED BY:

POWERED BY:

DESIGNED BY:

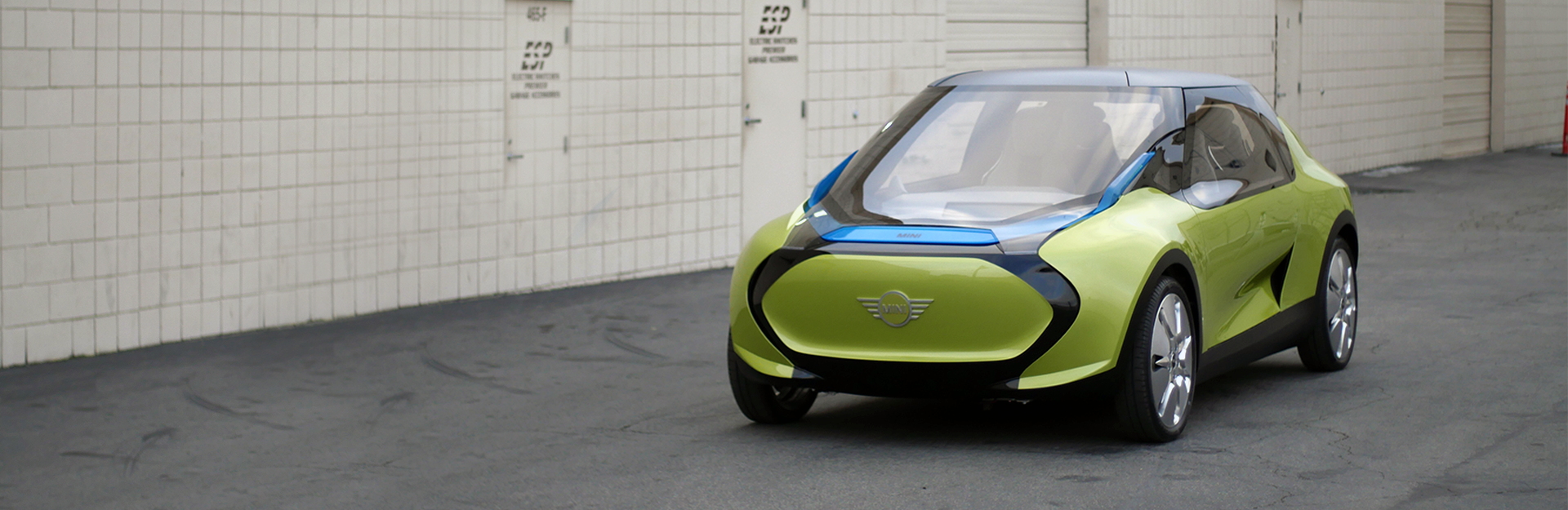

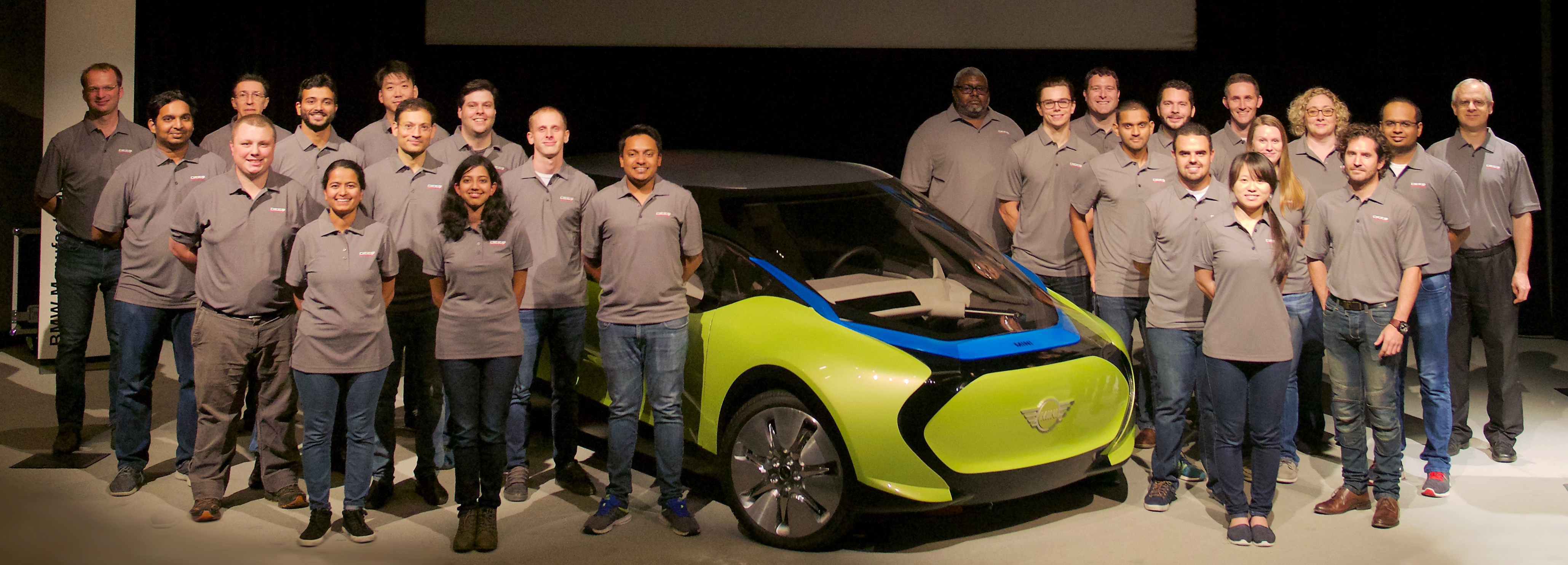

For the seventh generation of the Deep Orange program, students were challenged to re-envision the MINI to develop a fully-functional, drivable concept vehicle for the MINI brand targeting the premium U.S. market for 2025 and beyond.

With the BMW Group in Munich as the primary sponsor, students were in charge of determining which innovations would fit the MINI brand, as well as how these innovations would be integrated into the vehicle. As a result of this collaborative real-world educational experience, the students designed and built a functioning, drivable concept vehicle with multiple innovative features.

Started in 2014, the Deep Orange 7 vehicle was engineered around three primary goals: target the premium US market, maximize the use of interior space, and ensure a fun driving experience.

The 18-student team unveiled the fully-functional, drivable concept vehicle at the BMW Zentrum in Greer, South Carolina on October 14, 2017.

DEEP ORANGE 7 TECHNICAL OVERVIEW

DEEP ORANGE 7 STUDENT EXPERIENCE

MINI REINVENTED: 2025 AND BEYOND

The engineering of the Deep Orange 7 vehicle was designed around three primary goals: target the premium US market, maximize use of interior space, and is fun to drive..

MINI Open

An innovative vehicle design with a new “openness”, representing the desired MINI brand perceptions for 2025 and beyond. The traditional hood is replaced with a windshield that reaches all the way to the front of the vehicle and is easily lifted. Occupants are provided with a unique wide-open view outwards.

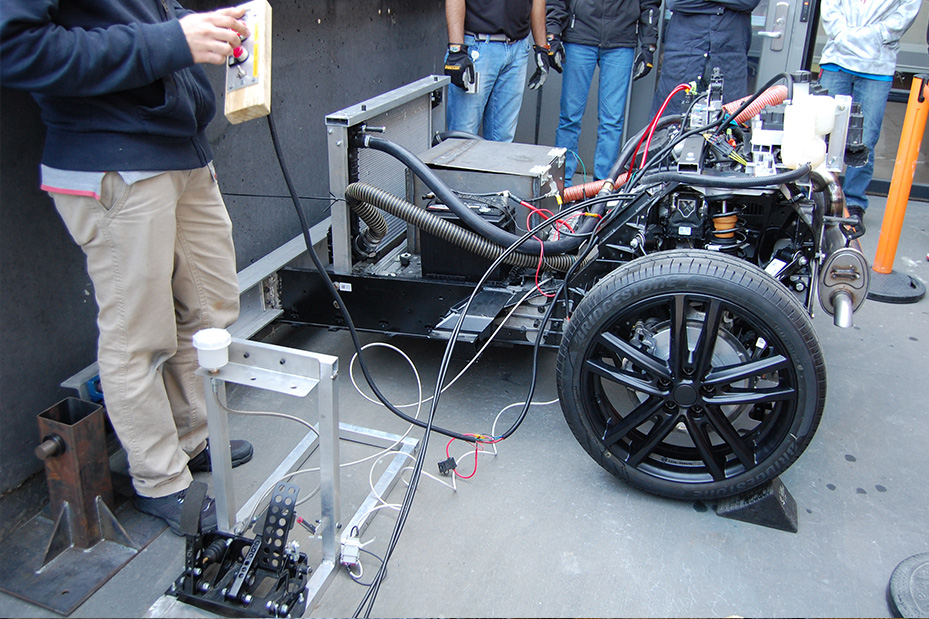

Scalable Powertrain

MINI meets the needs of the entire US market by offering a full powertrain spectrum. Options range from internal combustion engine only, plug-in hybrid to pure battery electric. All four variants are feasible within one vehicle platform. Fuel tanks and battery packs are installed in a modular fashion on the assembly line depending on the driver’s preference.

Modular Architecture

Partitioning the vehicle into a front, middle and rear modules drastically reduces assembly effort and floor space required. Consolidating the structural Body-In-White architecture into large subsystems will cut development, manufacturing and assembly cost. It also simplifies the creation of vehicle variants with interchangeable modules. Any version of the powertrain can fit into the vehicle without altering the Body-In-White.

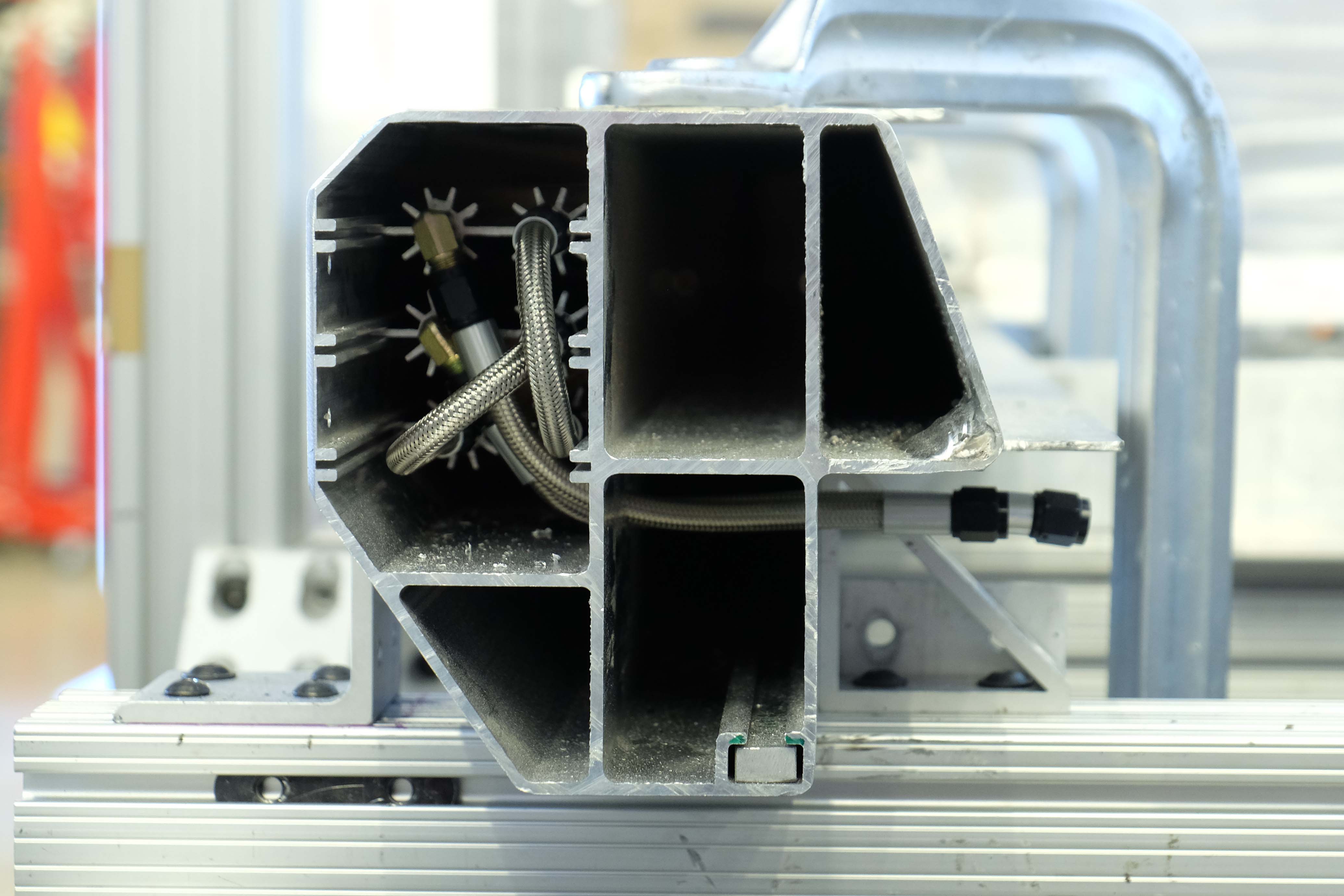

Rocker Cooling Panel

MINI is about clever use of space in a small package. The front electric motor cooling elements are functionally integrated inside the vehicle’s side sills, eliminating the need for separate radiators and providing easy access to the S3 space. Cooling channels are packaged within the otherwise empty side sills.

MINI Face

MINI FACE, an interactive system with “holographic” display replaces the conventional instrument cluster and center stack, decluttering the dashboard. The system features a personalized companion for each driver. MINI FACE anticipates preferences and needs of the driver and presents relevant information on the “holographic” display with three layers of depth. Hand gestures are used to interact with the system.

S3 and Origami Storage

See/Share/Store (S3) is an area for MINI owners to place items they are most passionate about. Origami Storage folds flat when not in use. The front canopy enables easy access to the S3 space which is connected to the vehicle interior through a floating dashboard. Occupants are provided with a unique wide-open view outwards as well as of their precious belongings.

MINI Parking Marshal Concept

MINI owners like to give back to their communities. The vertical sections of the lights are used to guide other drivers parking in front (or behind) the MINI to marshal them into their parking space. The lights illuminate incrementally as the parking vehicle approaches the MINI. Other cars are encouraged to park at a distance that prevents damage to both cars. It allows both drivers easy access to the front and rear of their vehicles.

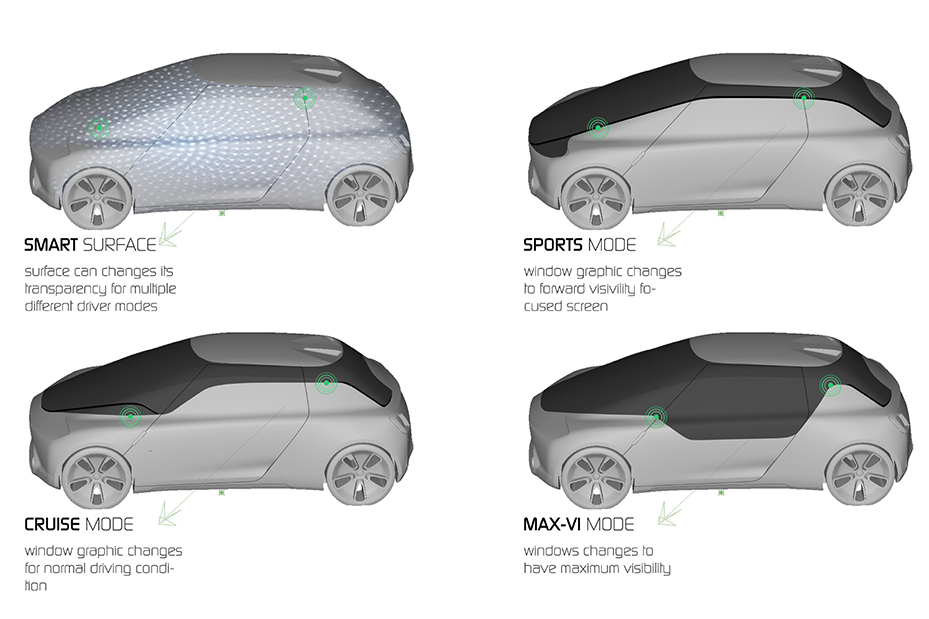

Digital Paint Concept

In the future, Digital Paint will allow on-the-fly external appearance changes depending on the mood and preferences of the driver. The glass may change in color, intensity and opacity. It could provide privacy to passengers traveling in autonomous vehicles. When activated, the glass will be transparent from the inside while appearing solid from the outside.

FROM CONCEPT TO COMPLETION

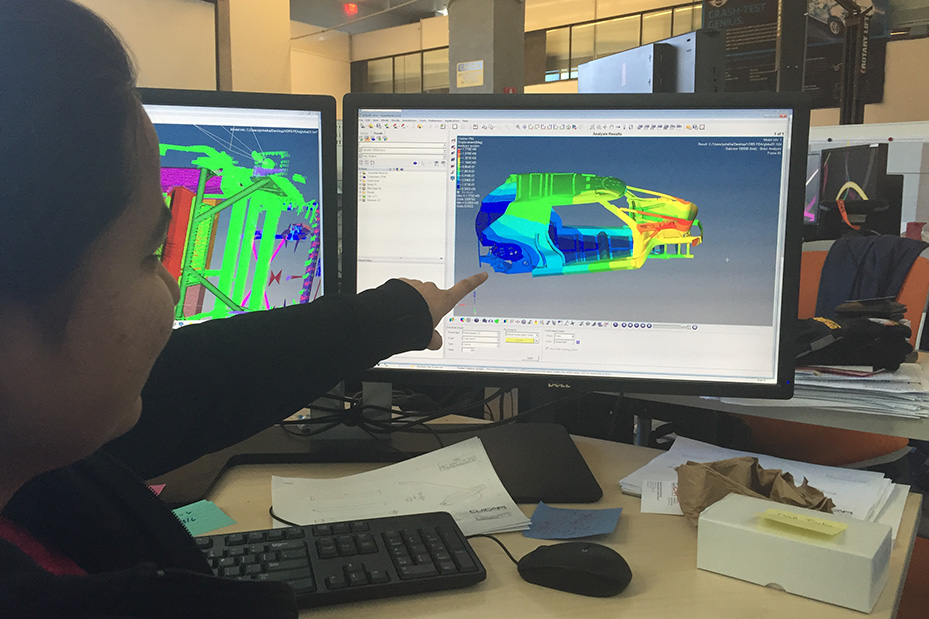

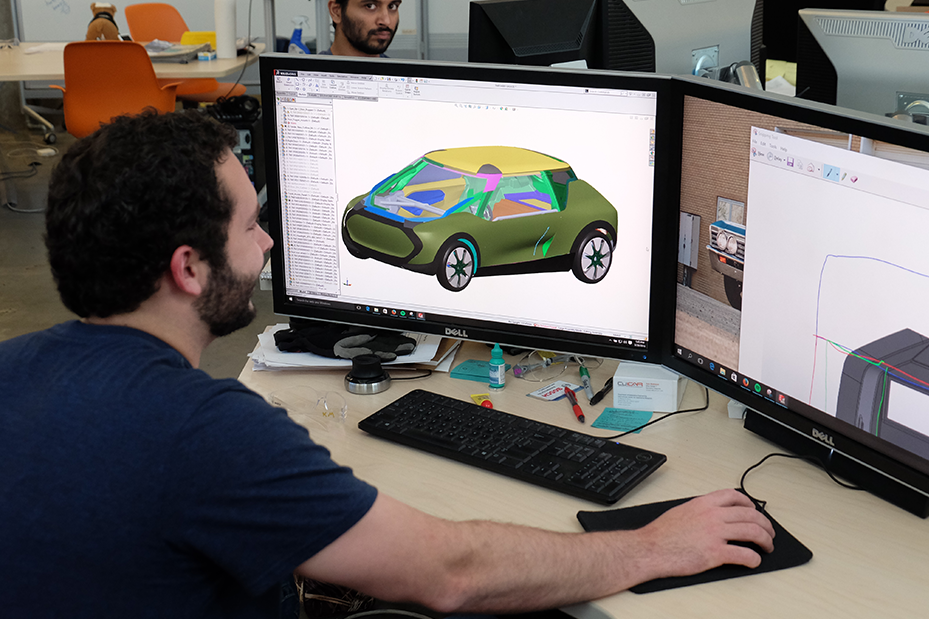

As part of the graduate automotive engineering program at CU-ICAR, students are given the unique opportunity to create and build a concept vehicle.

The project showcases advanced technologies and provides students an opportunity to work directly with automotive industry partners and experience all phases of the product development process.

FINISHED VEHICLE

The Deep Orange 7 vehicle was engineered around three primary goals: target the premium US market, maximize the use of interior space, and ensure a fun driving experience. Based on a thorough analysis of the future customer base for MINI in the US, the team competently addressed these customers’ aspirations through innovations and vehicle design.

DO7 Team

Automotive Engineering Students

Melvin Babbs

Manufacturing Integration

Kartik Bagga

Powertrain Team Lead

Mitch Beckman

Powertrain Energy Systems

Mitch Copley

Powertrain Integration

Matt Dwyer

Chassis Team Lead

Robert Knizek

Project Lead

Aaishwary Kulkarni

Interior Integration and Body-In-White Team

Vini Ribeiro Leao

Chassis Integration

Kyle Mattinson

Geometric Integration

Lauren Mims

Persona Expert

Bhoomika Narasimhan

Powertrain Controls and Simulation

Breno Schwambach

Powertrain Integration / HMI

Pratiksha Shelke

Body-In-White Team Lead

Rohan Shrivastava

Powertrain Controls and Simulation

Roshan Sai Subburaj

Functional Integration

Dheemanth Uppalapati

Powertrain Energy Systems

Yang Yang

Interior Team Lead

Jungyan Kang

Designer

PARTNERS

The following organizations have provided generous support, in-kind contributions, and mentoring to achieve the objectives of Deep Orange 9.