Deep Orange 9

ENGINEERED BY:

POWERED BY:

Engineered, built, and tested by Clemson students, Deep Orange 9 vehicle is a Next-Generation Rallycross racecar that envisions a clean, fuel-efficient car of the future that doesn’t compromise on performance.

With Honda R&D Americas, Inc. as the primary sponsor, students were challenged to create an innovative motorsports concept built for rallycross, a global sport that involves sprint-style racing with large jumps, aggressive jockeying, and drifting on a closed-loop track of dirt, asphalt, and mud.

Based on these parameters, students engineered around four primary goals: Improve fuel economy, reduce emissions, match current rallycross race performance, and minimize total vehicle operating costs.

After two years, the 19-student team unveiled their high-performance, fuel-efficient motorsports prototype at the ALL-IN Auto Rally at Clemson University on October 6, 2018.

The vehicle combines high-performance, ultra-tough racing features with a clean, fuel-efficient hybrid powertrain, advanced technical innovations, a lightweight/high-strength steel structure, and highly dynamic handling and acceleration. The concept is a response to rising fuel-efficiency standards and millennials’ interest in vehicles that are safe, clean, and exciting to drive.

DEEP ORANGE 9 Super Hype

DEEP ORANGE ATMOSPHERE

DEEP ORANGE 9 STUDENT EXPERIENCE

NEXTGEN RALLYCROSS

Students engineered Deep Orange 9 around four primary goals: Improve fuel economy, reduce emissions, match current rallycross race performance, and minimize total vehicle operating costs.

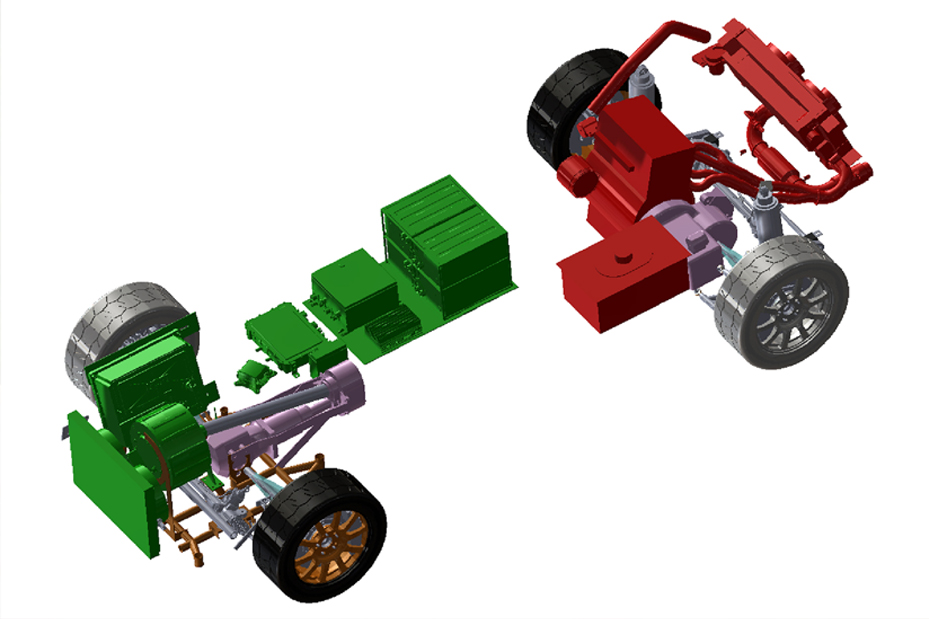

Hybrid Drivetrain

Most racecars focus on performance, not fuel economy. Students engineered an ultra-efficient hybrid drivetrain with 30% fuel economy improvements that keeps pace with power output and performance specs for existing rallycross cars. The hybrid powertrain works seamlessly with the driver through a student-developed integrated control system.

Race-ready Acceleration

The combined torque from the electric drivetrain and internal combustion engine helped achieve 0-60 mph in two seconds, making it competitive with existing rallycross cars.

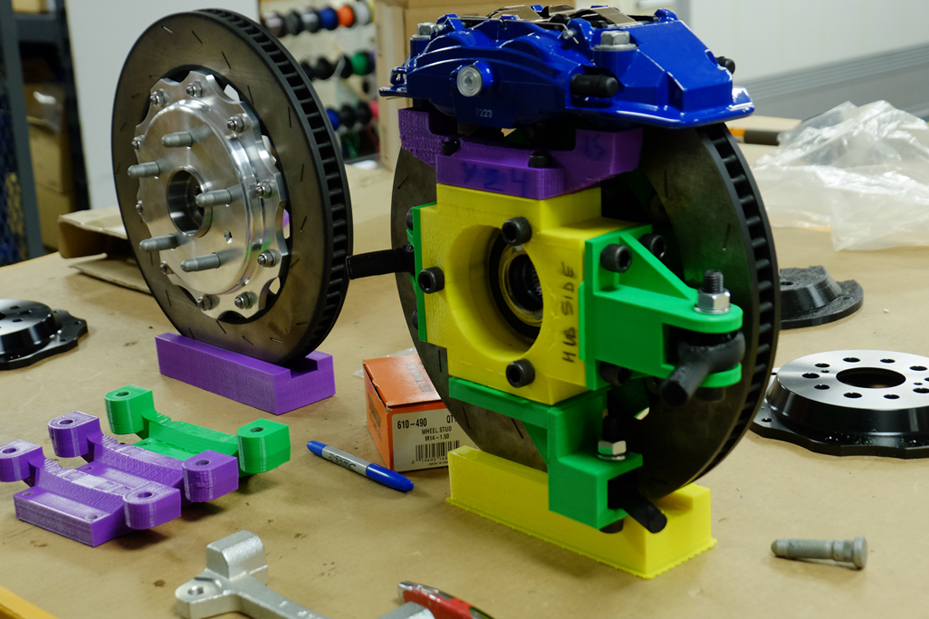

Regenerative Braking

Regenerative braking both improves fuel economy and allows the hybrid powertrain to operate in charge-sustaining mode, preventing the need to recharge vehicle batteries between races. This allows the vehicle to perform and operate with minimal maintenance throughout a race weekend.

Reduce Emissions

High performance doesn’t have to mean dirty. Using advanced simulations, students designed an integrated engine and after-treatment system that reduces hydrocarbon, carbon monoxide and nitrogen oxide emissions while also meeting the demands of an intense racing environment.

Four-Wheel Steering

Traditional rallycross drivers make sharp turns by locking the rear tires to cause a skid, resulting in lost speed and diminished handling during a race. Students designed an electronic four-wheel steering system that allows for faster cornering and improved maneuverability by avoiding the need to lock the rear tires. In the case of Deep Orange 9, this feature also improves fuel economy by capturing lost energy through the wheels.

Semi-Active Suspension

As a mixed-surface race, rallycross forces engineers to make a compromise between performing well on pavement versus dirt and gravel. For Deep Orange 9, students designed a semi-active suspension system that adapts on the fly to changing surfaces, eliminating the need for a compromise.

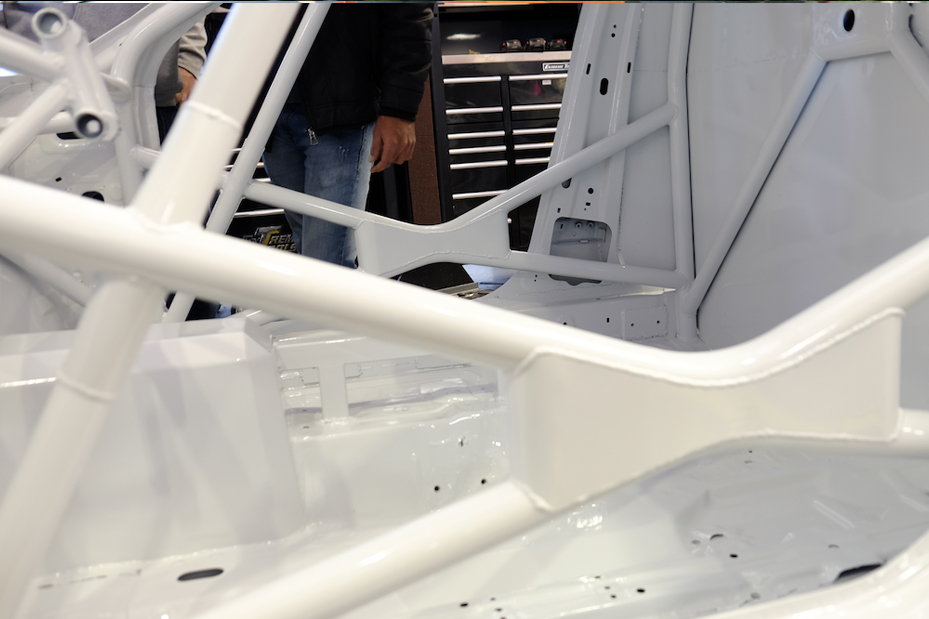

High-Strength Steel Structure

Rallycross involves lots of jumps and aggressive jockeying that you wouldn’t see in a consumer-driving environment. Students were challenged to design a novel packaging system to accommodate the mid-engine through-the-road hybrid powertrain layout and ultra-long travel suspension within the strict safety guidelines required for racing. The result was a heavily optimized, high-strength steel structure that works efficiently with the heavily modified stock chassis.

Virtual Reality Ride-Along Experience

Rallycross fans are digital natives who expect not only to watch the race, but be a part of it. By incorporating a virtual reality ride-along experience, attendees can take the digital front seat on the track and cheer on their favorite racer wherever they are.

FROM CONCEPT TO COMPLETION

As part of the graduate automotive engineering program at CU-ICAR, students are given the unique opportunity to create and build a concept vehicle.

The project showcases advanced technologies and provides students an opportunity to work directly with automotive industry partners and experience all phases of the product development process.

FINISHED VEHICLE

Engineered, built, and tested by Clemson students, the Deep Orange 9 vehicle is a Next-Generation Rallycross racecar that disrupts market perceptions of energy-efficient vehicles by showing they can meet extreme performance demands in a safe, clean way.

The vehicle combines high-performance, ultra-tough racing features with a clean, fuel-efficient hybrid powertrain, advanced technical innovations, a lightweight/high-strength steel structure, and highly dynamic handling and acceleration.

DO9 Team

Automotive Engineering Students and Leadership

Nandanshri Bagadi

Powertrain - Supervisory Control

PARTNERS

The following organizations have provided generous support, in-kind contributions, and mentoring to achieve the objectives of Deep Orange 9.