Process. Prototype. Program.

Expanding Your Research Capabilities, From Data Acquisition to Software

Drawing on healthcare, industrial, and research lab experience, Clemson University's Machining and Technical Services offers electronics solutions and support for research projects, from process controls to software modifications.

The electronics division of Clemson University's Machining and Technical Services is a specialized team dedicated to providing comprehensive solutions and support for projects across diverse disciplines. The electronics team works with various apparatus and process controls, including temperature, pressure, flow, and data acquisition, as well as writing and modifying software using C++, C#, PLC, LabVIEW, and Arduino environments. Information Technology support, modifications and maintenance of editable software can be provided.

In the News

Machining and Technical Services | Recent Projects

Easier Data Collection

A project by Dr. Thies examines how a waste byproduct from the paper manufacturing industry could be converted into a usable source of energy. To make the data collection easier, the electronics division created the programming using Labview, allowing researchers to see all measurements in one place. From the single screen, they measure temperatures, flow rates, and physical properties throughout the lignin separation process.

Mark Thies is a professor in the Department of Chemical and Biomolecular Engineering. One of his main research interests is that of creating value from renewable and refinable polymers.

“With their machining capabilities, MTS helped us design and construct a customized reactor for an advanced materials DoD project – and at a fraction of the cost of a commercial unit that didn't meet our needs. Their fabrication and welding capabilities have been critical for the design and assembly of patented processes for converting waste biomass into renewable polymers. If that wasn't enough, MTS electronics capabilities recently were used to enhance computer control of the above process so that now the polymers have superior properties to support a new research direction.”

Mark ThiesChemical Engineering

Control Box

Dr. Wade Hawkins is the Optical Fiber Laboratories Director at COMSET, the Center for Optical Materials Science and Engineering Technologies. Hawkins needed a vacuum shield to remove hazardous gasses from the workspace and an electrical control box to control temperatures. The electronics division completed the heater control box.

COMSET Research

Capabilities

01

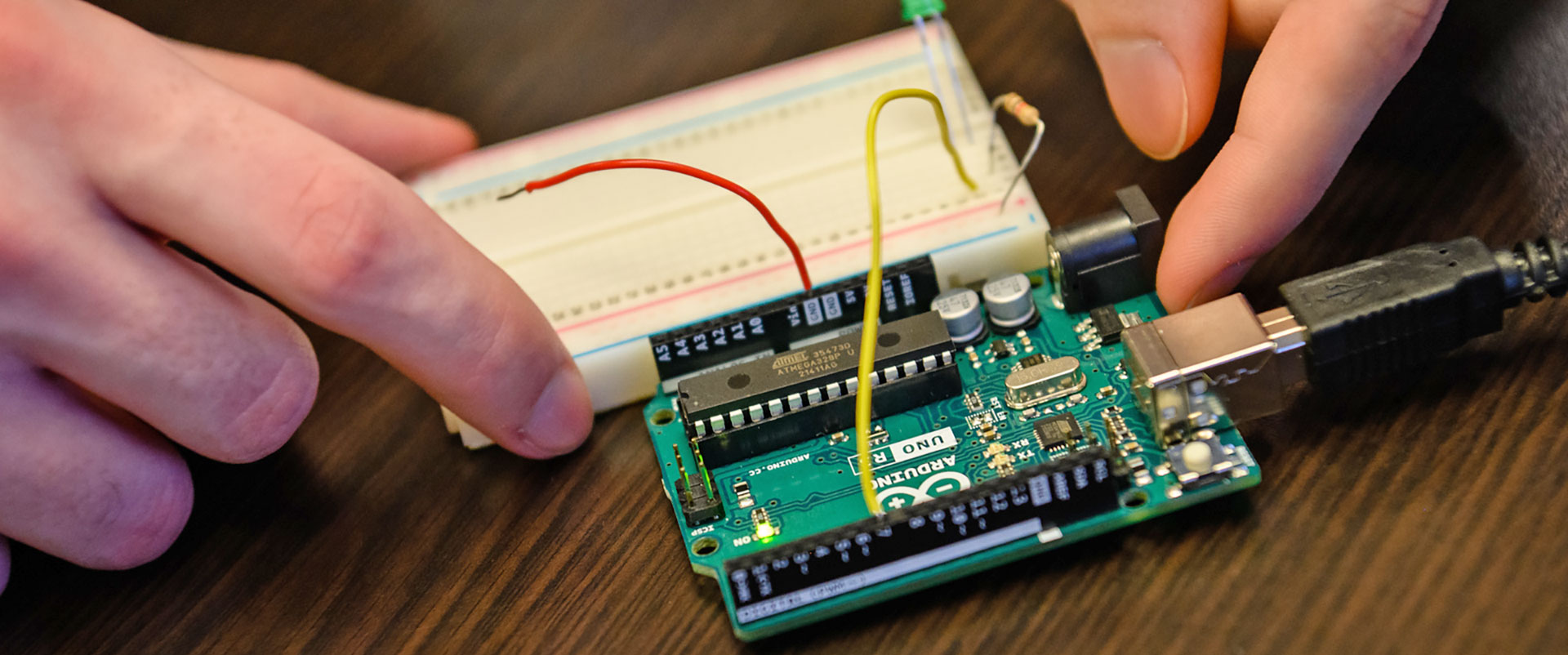

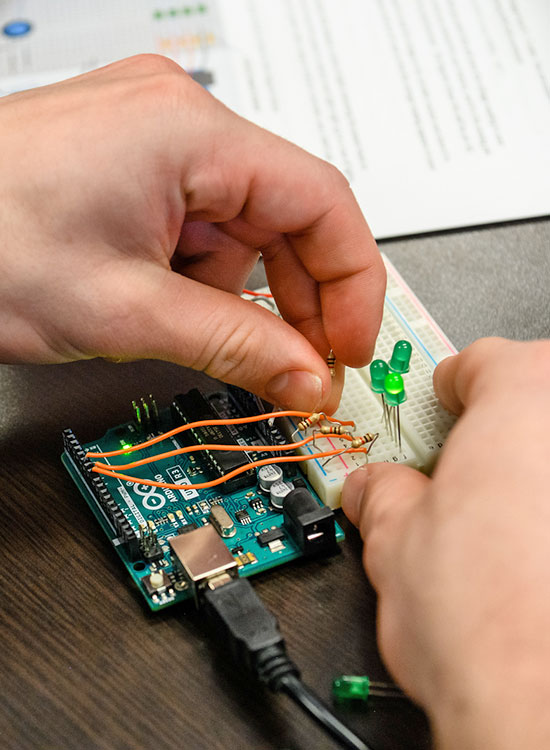

Electronics Programming

MTS can perform electronics software design, troubleshooting, and programming. Troubleshooting involves identifying and diagnosing problems or malfunctions in electronic circuits, devices, or systems, pinpointing the root cause of an issue, and determining the necessary steps to fix it. The process also involves debugging skills to identify and correct software-related issues.

Our Team members have extensive knowledge of writing and modifying software using C++, C#, PLC, LabVIEW, and Arduino environments.

02

Instrumentation and Controls

Instrumentation and controls focus on the measurement, monitoring, management, and automation of industrial processes and systems and are essential for the efficient and reliable operation of complex processes and equipment.

Applications include manufacturing automation, chemical processing, power generation, water treatment, building automation, aerospace, and traffic control systems.

Chris Addington

Electronics Technician Engineering Associate II

Joshua Hilley

Systems Programmer/ Developer II