Design. Develop. Deliver.

Skilled Designers Transforming Your Ideas Into Tangible Reality

Clemson University's MTS 3D printing division offers design optimization, material selection, printer setup, calibration, and troubleshooting services. They possess in-depth knowledge of various printing methods and provide comprehensive research support.

With their technical experience and proficiency, the 3D printing division assists in optimizing designs and models for 3D printing. The team possesses in-depth knowledge of various printing methods, including fused deposition modeling, fusion jet technology, and material jetting, ensuring high-quality and accurate prints. Dedicated to providing comprehensive research support, the print shop collaborates closely with clients to bring their ideas to life using the power and speed of 3D printing technology.

In the News

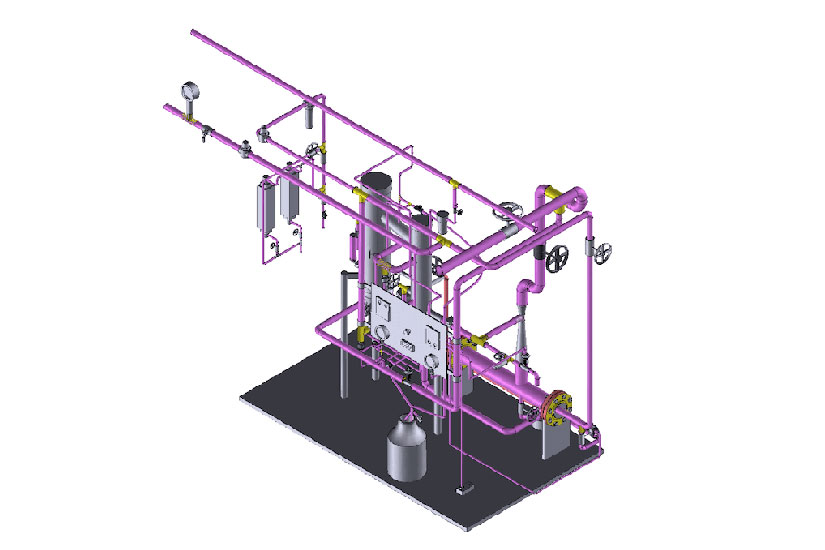

Machining and Technical Services | Recent Projects

Precise Prototypes

Bioengineering students often use the lab's 3D printers to print prototypes of new products—like a new type of catheter or an apparatus to hold an infant's head in place during cranial surgery. Many of the students' designs include small, detailed features that need to be both strong and precise.

The FDm printers encourage students to push the boundaries of their imagination - they no longer are restricted by previous design constraints.

“As far as being able to offer these capabilities to students, Desjardins said: "They've been able to realize their dream, what they're thinking in their head, what they're seeing on their computer, so it's really a moment for them of true learning inflection. We're exposing them to how 3D printing processes work, and they're able to use that in their education, but we're also teaching them how things are going to be made in the future.”

John DesjardinsBioengineering

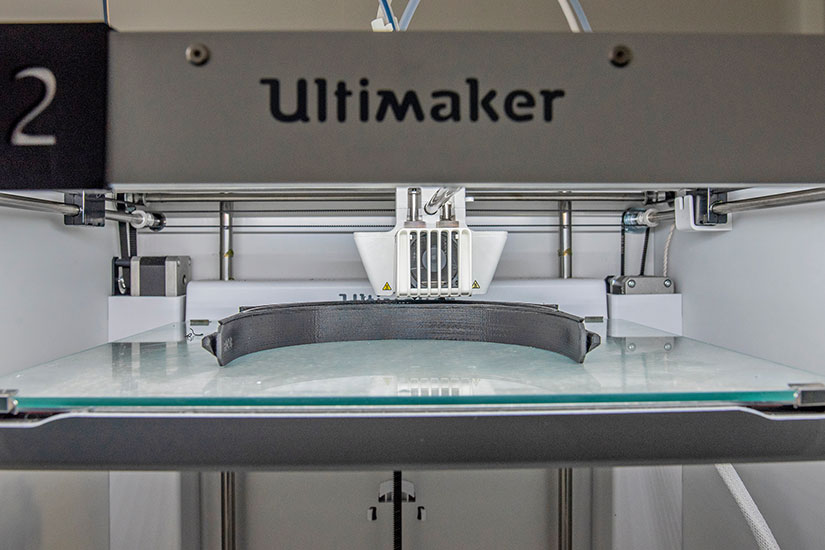

Ventilator Prototypes

Needing to create a 3D ventilator expander prototype after medical supply shortages, Pruett provided potentially life-saving proof of concept prototypes to one of Clemson University's upstate healthcare partners. The prototype was tested with medical manikins, and it met the appropriate breathing requirements without difficulty.

Healthcare PrototypingMulticolor Modeling

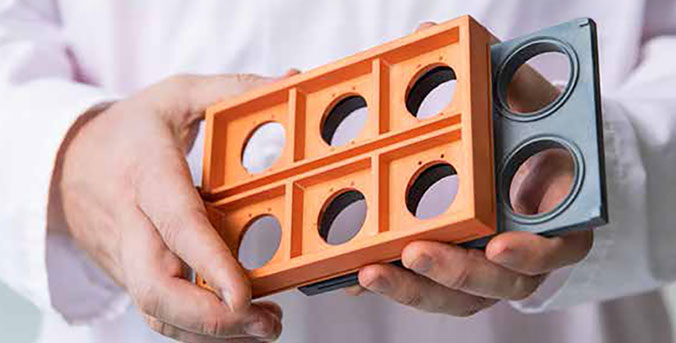

Each model Chris Norfolk, a senior lecturer in the Department of Chemical and Biomolecular Engineering, has created is one color and shows one type of atom. But when he began developing models of alloys that contain several colors representing different types of atoms, he enlisted the help of Machining and Technical Services for assistance in the extra details.

Classroom Models

Capabilities

01

Fused Deposition Modeling

Fused Deposition Modeling (FDM) is a popular additive manufacturing or 3D printing technology used to create three-dimensional objects layer by layer. It is known for its simplicity, reliability, and versatility, making it widely used for 3D printing applications.

Polycarbonate and ABS allow for high tensile strength and wide-color variation abilities.

02

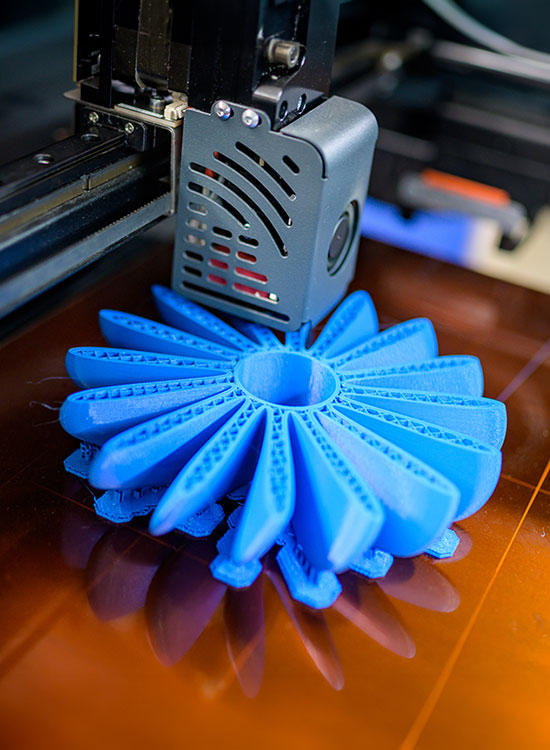

3D Color Printing

3D color printing, also known as 3D color additive manufacturing, is a technology that allows you to produce three-dimensional objects with color and texture directly from digital files. Traditional methods focus on adding a single color or material, whereas 3D color printing allows the addition of multiple colors and textures directly into the printed object during fabrication.

Our equipment produces fully functional parts with fine details and exceptional accuracy in full color.

03

Polyjet 3D Printing

PolyJet 3D printing is an additive manufacturing technology that uses inkjet-style printing heads to jet layers of photopolymer materials onto a build platform. PolyJet builds objects layer by layer. This process creates three-dimensional objects by precisely depositing and curing these materials layer by layer.

This machine will allow materials to be blended together to achieve many hardness and flexibility options.

Tim Pruett

Additive Manufacturing Technician Lab Tech. III

Jacob Gantt

Welder / Additive Manufacturing Technician Lab Tech. II