Draft. Design. Develop.

Project Collaboration, From Blueprints To Three-Dimensional Modeling

The Design Consultation, Reverse Engineering, and 3D Modeling Division includes staff from each division dedicated to providing comprehensive services in design, reverse engineering, and 3D modeling, as well as the creation of detailed blueprints and technical drawings. Client collaboration is a key component throughout the process.

With a deep understanding of engineering principles and cutting-edge technologies, this division offers expertise in various aspects of product development and manufacturing optimization. Team members have extensive knowledge of CAD software, 3D scanning technologies, and manufacturing processes. They work closely with clients, collaborating on projects and providing valuable insights on materials and manufacturing processes through the design and modeling stages.

In the News

Machining and Technical Services | Recent Projects

Built New, Better Designed

When blood vessels are damaged, fibroblasts are deployed to make repairs by synthesizing collagen. However, in people with diabetes, fibroblasts produce too much collagen. Bioreactors can be used to simulate vascular biomechanics and diabetic conditions. MTS modified the original Vascular Bioreactors to work better, designed and modeled in Solidworks, and built new, better-designed Vascular Bioreactors.

Researchers launched a project to better understand cardiovascular - laying the groundwork for future studies aimed at finding new treatments.

“From the very beginning, they sat down with me and tried to understand absolutely everything that I was doing because they envisioned that in order to give out a really good product, they needed to understand my needs.”

Juan Carlos CarrilloPh.D. StudentBioengineering

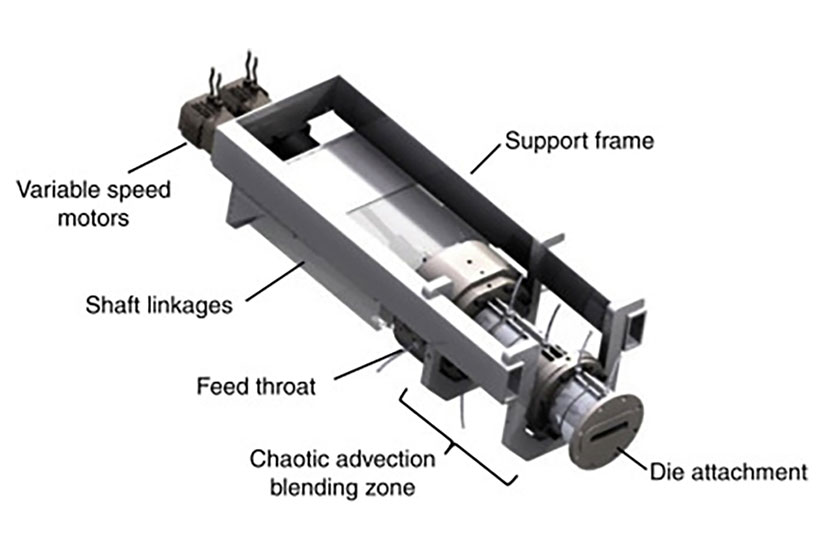

Extending Shelf Life

MTS aided in designing a smart blending extruding die and machined the components to produce a polymer film containing vitamins and other additives to extend the shelf life of food goods such as MREs (Meals Ready to Eat). The Smart Blending device, supplied with a license from Clemson University, creates melt structures by folding and stretching layers.

Learn More

Capabilities

01

Design and 3D Modeling

Our team works closely with clients, collaborating on projects and providing valuable insights throughout the design and modeling stages to develop and refine ideas. Our 3D models create digital representations to allow for accurate visualization and simulation of the design; these can be used for structural analysis, fluid dynamics, motion studies, and to evaluate the performance and behavior of the prototype.

Our Team members have extensive knowledge of CAD software and 3D scanning technology to assist with modeling, blueprints, and technical drawings.

02

Reverse Engineering

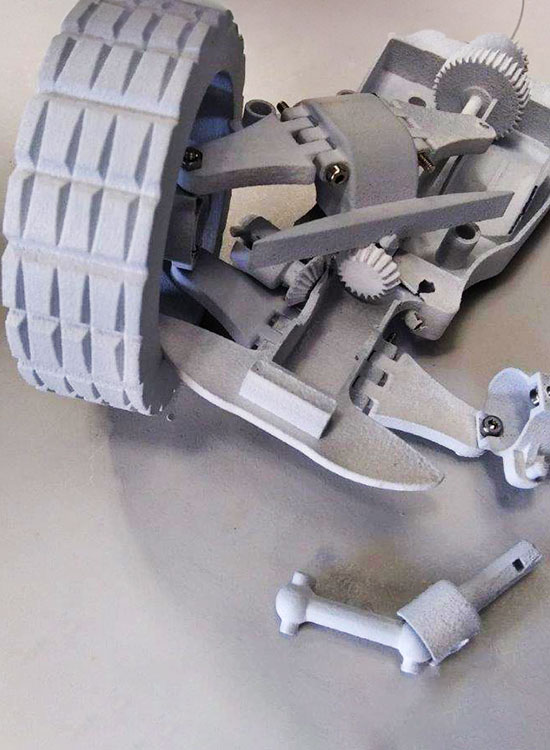

Reverse engineering is dissecting, analyzing, and understanding a product, system, or component to determine how it works or was designed. This knowledge can be invaluable for troubleshooting issues, making improvements, or creating compatible products.

The process typically involves data collection, component analysis, and detailed documentation for future reference.

Jeff Holliday

Machine Shop Manager Lab Tech IV

Dustin Gravley

Machine Shop Assistant Manager Lab Tech. III

Truman Nicholson

CNC Shop Manager Lab Tech. IV

Sam Biemann

Precision Machinist Lab Tech. II

Bill Simmons

Precision Machinist Lab Tech. II

Jon Simpson

Precision Machinist Lab Tech. II

Chris Addington

Electronics Technician Engineering Associate II

Joshua Hilley

Systems Programmer/ Developer II

Dock Houston

Fabrication Shop Manager Lab Tech. IV

Scott Kaufman

Lab Technician Lab Tech. III

Jacob Gantt

Welder / Additive Manufacturing Technician Lab Tech. II

Tim Pruett

Additive Manufacturing Technician Lab Tech. III