Plan. Prepare. Precision.

Experienced Metalworkers Specializing In High-Quality Custom Designs

MTS has a comprehensive welding shop and a team of experienced fabricators who can weld microscopic components all the way up to heavy plates and fixtures.

The welding and fabrication division at MTS is equipped with a comprehensive welding shop equipped with tools and machines, including welding equipment, plasma cutters, metal shears, brakes, and more. The capabilities of the welding shop include laser, TIG, MIG, and stick welding, as well as soldering and brazing an extensive range of materials. MTS's welding and fabrication personnel are experienced metalworkers with the necessary skills and knowledge to provide high-quality custom metal fabrication and welding services.

In the News

Machining and Technical Services | Recent Projects

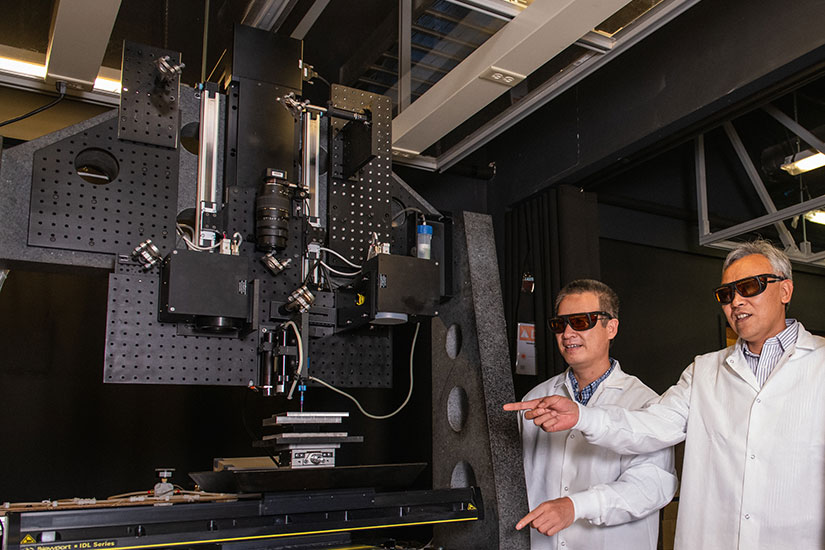

Photonic Crystal Research

According to Joseph Kolis, he's one of a handful of researchers who grow crystals using hydrothermal synthesis, so he and his students have had to build their own high-pressure growth equipment. Producing quality material under these extreme conditions wouldn't be possible without the expertise of Clemson University's MTS group, which machined and maintained autoclave components.

An emerging technology called quantum computing will revolutionize a range of fields, including encryption and cybersecurity, drug discovery and weather forecasting.

“Those guys are really good, and they have contributed a lot to my research. Not only do they do the machining, but they can give me design suggestions on the equipment. They're a critical part of this [quantum computing] project.”

Joseph KolisChemistry

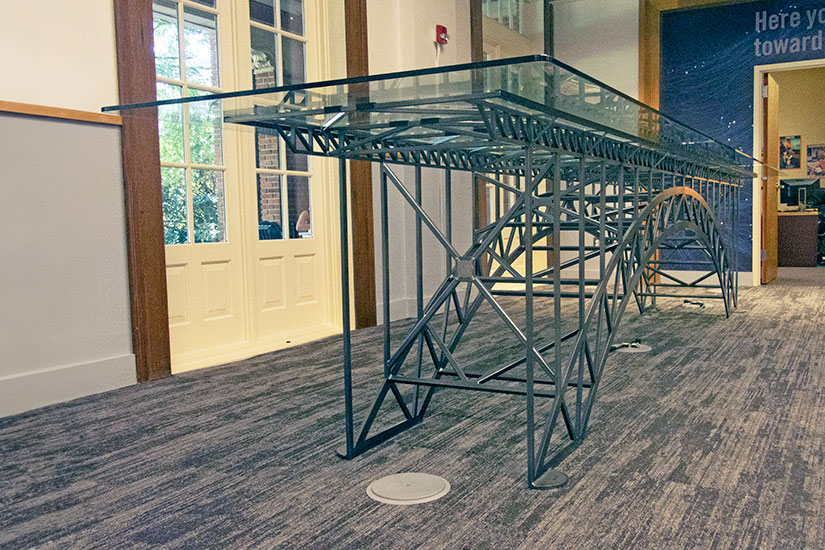

Holtzendorff Bridge Table

In 2018-19, Holtzendorff Hall underwent a lobby remodel that included a dedicated study area, digital monitors, and signage. Machining and Technical Services were tasked with designing a table for the front lobby area to connect the space even further to the confluence of engineering design and practicality. What started as a sketched idea became a rugged yet delightful metal and glass bridge that blends well into its new home.

Holtzendorff HistoryLowering Emissions

With a goal to generate power more efficiently while lowering emissions, researchers are focusing on sensors at power plants. The two power-plant sensors they are developing could help watch for equipment failures, helping lower utility maintenance costs. One of the power-plant sensors would monitor boiler tubes, which the Welding and Fabrication Division laser-welded dissimilar metals and TIG welded on the stainless steel tubing for the sensors.

Power Plant Sensors

Better Flow

This funnel was specifically designed to fit an existing extruder setup to allow for easier refills and better flow into the extruder. Machining and Technical Services designed and manufactured 4 of these at the request of a faculty member from material science.

Capabilities

01

Welding

Welding is a fabrication process used to permanently join pieces of metal or thermoplastic materials by melting or fusing them. Incorporating welding with lasers creates a high-precision and efficient welding process by using a focused laser beam as the heat source in joining.

It is particularly well-suited for fusing thin materials, small components, and materials that are difficult to weld using traditional methods.

02

Sheet Metal Fabrication

Sheet metal fabrication involves shaping and forming thin sheets of metal into a wide range of components and products. The metal can be made from various materials, including steel, aluminum, stainless steel, copper, and brass, with the choice of material depending on the desired strength, corrosion resistance, appearance, and cost.

The material's versatility allows it to be easily manipulated to create various structures, enclosures, and parts.

Dock Houston

Fabrication Shop Manager Lab Tech. IV

Scott Kaufman

Lab Technician Lab Tech. III

Jacob Gantt

Welder / Additive Manufacturing Technician Lab Tech. II