Hitachi Fellowship

The Hitachi High-Tech Electron Microscopy Annual Fellowship provides $25,000 each year to support a graduate student using the Clemson University Electron Microscopy Facility to conduct research as part of their doctoral studies. Hitachi has been a long-time supporter of the Electron Microscopy Facility, helping to create the high-tech lab in the mid-1990s and establishing the fellowship in 2014. Nominations for the Fellowship are accepted each Fall.

Hitachi Fellowship Recipients

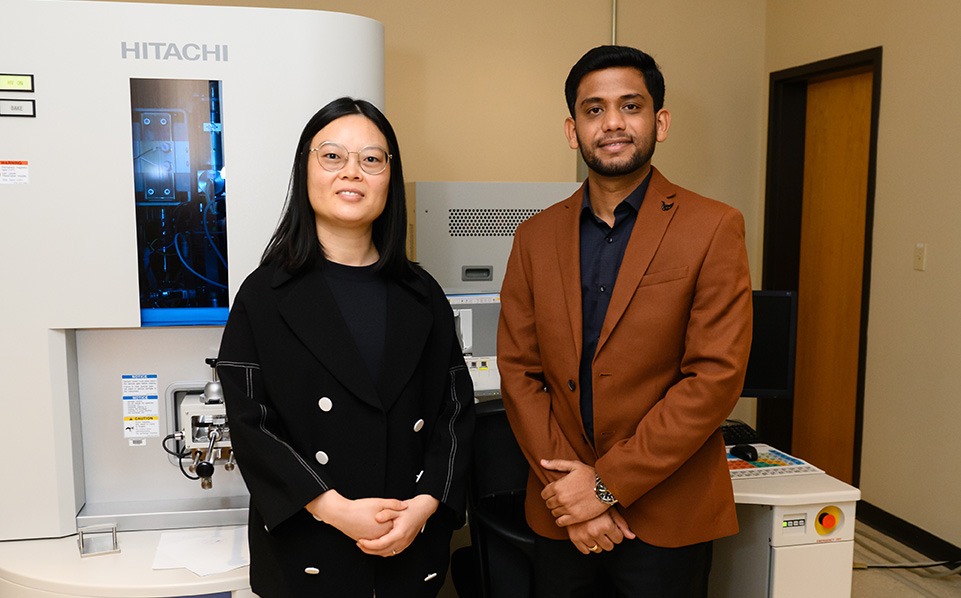

2024 Recipients: Som Dixit and Shinto Francis

This year two Clemson University Ph.D. students Som Dixit and Shinto Francis received fellowships from Hitachi High-Tech America Inc. to support their research on additive manufacturing and quantum computing, respectively. Each student received a $25,000 fellowship to continue their research and complete their doctoral degrees.

Automotive Engineering

Advisor: Shunyu Liu

An automotive engineering Ph.D. student, Dixit is working to unlock the potential of additive manufacturing to produce high-performance materials with vast applications across the military, automotive, energy and nuclear sectors. His research focuses on developing innovative materials like metal-ceramic multifunctional composites, high-entropy alloys and various industrial alloys.

He uses highly advanced electron microscopy at Clemson University to analyze additively manufactured components at different scales, characterizing their microstructural features, defect evolutions, as well as physical and chemical interactions at interfaces of dissimilar materials.

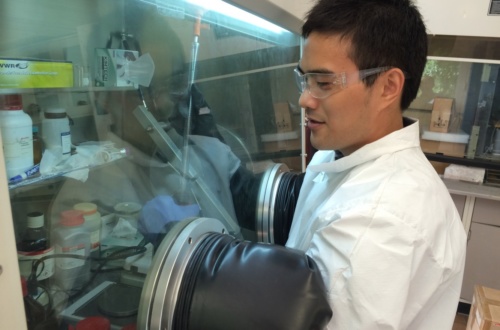

Physics And Astronomy

Advisor: Ramakrishna Podila

Francis, a Ph.D. student in the Department of Physics and Astronomy, is working to develop systems to support quantum computing, which holds promise to solve complex problems not currently supported by classic supercomputers.

Conventional computers utilize binary form (1s and Os) to encode information. The fundamental building blocks of quantum computing, however, are qubits, or quantum bits. While powerful, qubits are highly susceptible to outside noise or interference. Shinto is working to build periodic defects such as nitrogen vacancy centers that could be less susceptible to external disturbance.

-

2023 Recipient: Afreen Sultana

2023 Recipient: Afreen Sultana

Food, Nutrition, and Packaging

Advisor: Scott Whiteside

Sultana is working to strengthen starch-based coatings by using cellulose nanocrystals taken from the invasive kudzu plant to improve paper-based packaging’s resistance to liquids and gases. For the starch, Sultana extracts from pearl millet, a summer hay crop that is inexpensive to grow. She’ll analyze materials at the molecular level using advanced equipment at Clemson’s Electron Microscopy Facility to finetune these biofilms. -

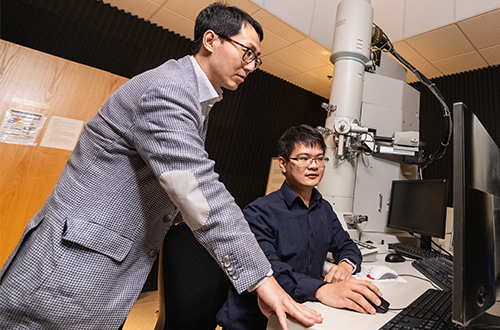

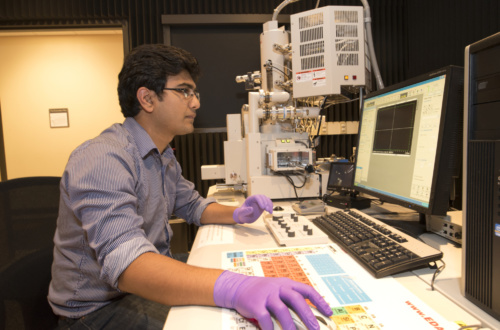

2022 Recipient: Zehua Jin

2022 Recipient: Zehua Jin

Chemical Engineering

Advisor: Ming Yang

Jin is doing research on the development of advanced catalytic materials to convert carbon dioxide into value-added chemicals. The research aims to support the mitigation of greenhouse gas emissions and production of renewable fuel. Jin is studying electrocatalytic carbon dioxide reduction, a process by which catalysts are added to solids or liquids to induce beneficial chemical reactions. In this case, Jin would selectivity disperse platinum-group metals (PGM) as isolated atoms on copper nanoparticles. -

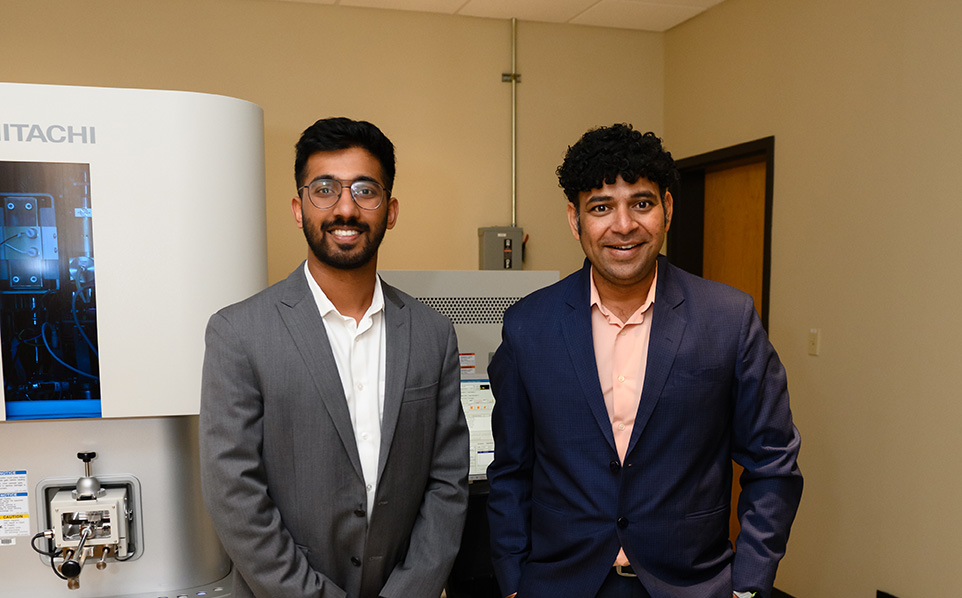

2021 Recipient: Hongkui Zheng

2021 Recipient: Hongkui Zheng

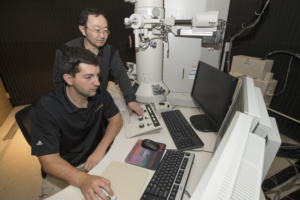

Materials Science and Engineering

Advisor: Kai He

Zheng is working to develop and implement transmission electron microscopy (TEM) techniques that will allow for the investigation of materials used in batteries. Most battery materials contain lithium, which is highly reactive with air. Zheng is working on a method to safely transfer material into the vacuum within the microscope without exposure. He also is working to cycle the battery within the microscope to mimic its working condition in a real battery cell. Then, he can watch the real-time evolution of the structures and chemical reactions. -

2020 Recipient: Saheem Absar

2020 Recipient: Saheem Absar

Mechanical Engineering

Advisor: Hongseok Choi

Ph.D. student Saheem Absar is using advanced electron microscopy techniques to analyze the effect of nanoparticles on the behavior of gas bubbles during the solidification of molten metal. Knowledge gained through Absar’s experiments could be useful for controlling the pore formation during the manufacture of metal foams. Metal foams are lightweight, energy absorbing materials that are desirable in automotive and aerospace applications. -

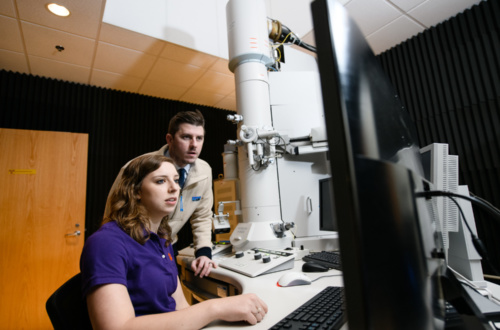

2019 Recipient: Allison Domhoff

2019 Recipient: Allison Domhoff

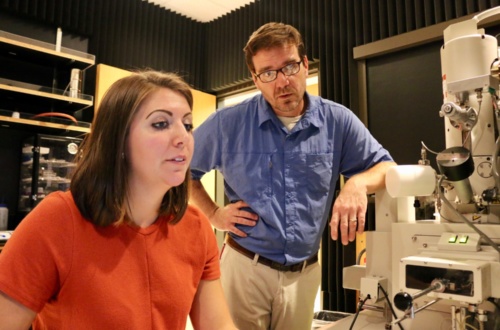

Chemical and Biomolecular Engineering

Advisor: Eric Davis

Domhoff, a chemical and biomolecular engineering student, is working to develop nanocomposite materials for batteries that support energy generation at large wind and solar farms. The technology could reduce the cost of renewable energies, thus making them more prevalent in utility portfolios. Electron microscopy allows Domhoff to research nanometer-sized particles in the battery’s membrane so she can manipulate its surface chemistries to improve battery life and performance. -

2018 Recipient: Kathryn Peruski

2018 Recipient: Kathryn Peruski

Environmental Engineering and Earth Sciences

Advisor: Brian PowellUsing Hitachi’s super-magnifying microscopes, Peruski has captured the miniscule fragmenting of neptunium, a radioactive byproduct of nuclear power generation that is stored underground. Through her research, Peruski hopes to better understand what causes neptunium to break so engineers can design effective storage methods for nuclear waste. She analyzed several neptunium samples exposed to environmental variables and documented their changes over time.

-

2017 Recipient: Brandt Ruszkiewicz

2017 Recipient: Brandt Ruszkiewicz

Automotive Engineering

Advisor: Laine Mears

Ruszkiewicz used Hitachi electron microscopes at Clemson to examine how a super-strong type of aluminum reacts to electricity. His research could lead to new ways of forming and joining together automotive parts. This work could help make cars lighter and more fuel efficient. -

2016 Recipient: Monsur Islam

2016 Recipient: Monsur Islam

Mechanical Engineering

Advisor: Rodrigo Martinez

Islam was using renewable resources instead of coal and petroleum to create carbides that are important for products ranging from surgical tools and jewelry to hot-gas filters and shock absorbers. Using the Hitachi microscopes. Islam was able to examine the properties of the carbides he creates. He can see critical elements that are invisible to the naked eye, such as porosity, composition and grain size. Islam can then make adjustments to the mix of raw materials that go into the carbide. -

2015 Recipient: Zhaoxi Chen

2015 Recipient: Zhaoxi Chen

Materials Science and Engineering

Advisor: Fei Peng

Chen's research was based on the development of coatings for high-speed jets and protection for electrical equipment in harsh environments.The lab’s electron beam microscopes allow researchers to magnify specimens at a much higher resolution than optical light microscopes. One of the lab’s microscopes - the H-9500 Transmission Electron Microscope - is so powerful it can make individual atoms visible. -

2014 Recipient: Yunsong Zhao

2014 Recipient: Yunsong Zhao

Electrical and Computer Engineering

Advisor: Lin Zhu

Zhao’s work was focused on making semiconductor lasers powerful while maintaining good beam quality for use in research and industry. The microscopes use electrons to magnify specimens at a much higher resolution than optical microscopes. The super-magnification has a wide range of uses in research and industry. For example, electron microscopes are used for quality control, computer-chip manufacturing and analyzing viruses.